Search below by license plate or part number:

I want to search by brand and type

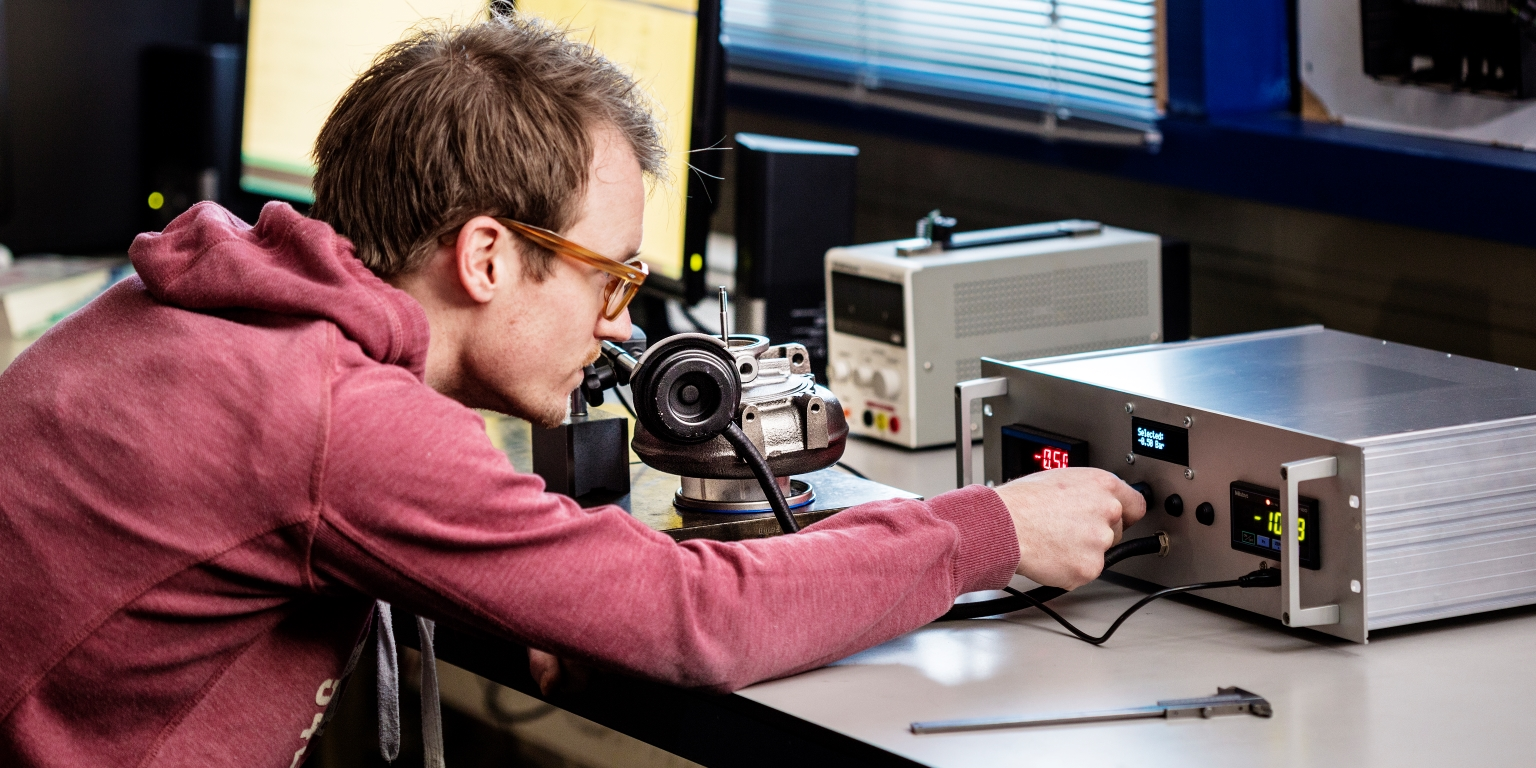

Our R&D department consists of a team of technical specialists. They work closely with our experienced professionals on the shop floor. On one hand, they get to know the market demand, and on the other hand, they keep everyone updated on new techniques. To verify the performance of these techniques, we continuously invest in advanced testing equipment.

We continue to evolve. Because we have a passion for our profession, but also because our work is of great significance to the circular economy. Products that have been used deserve a second life. With our expert and experienced team, we are committed to that. Now and in the future.